Description

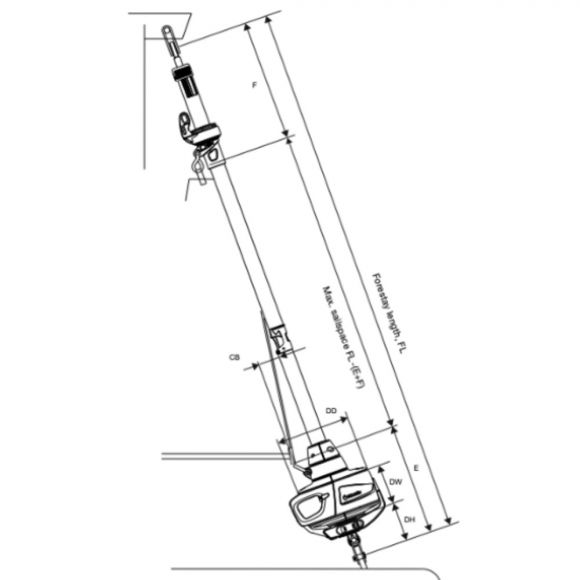

| Description | Imperial | Metric |

|---|---|---|

| Forestay diameter | 5/16 in. | 8.00 mm. |

| Rod diam. | -12.00 (7.10) mm. | -12.00 (7.10) mm. |

| Max righting moment at 30 degrees heel – Masthead rig | 37.00 kNm | 37.00 kNm |

| Max righting moment at 30 degrees heel – Fractional rig | 45.00 kNm | 45.00 kNm |

| Approx. Displacement – Masthead rig | 16534.70 lb. | 7.50 ton. |

| Approx. Displacement – Fractional rig | 19841.60 lb. | 9.00 ton. |

| DH | 4 1/2 in. | 115.00 mm. |

| DW | 3 9/16 in. | 90.00 mm. |

| DD | 7 1/4 in. | 185.00 mm. |

| CB | 2 3/8 in. | 60.00 mm. |

| E | 10 13/16 in. | 275.00 mm. |

| F | 16 3/4 in. | 425.00 mm. |

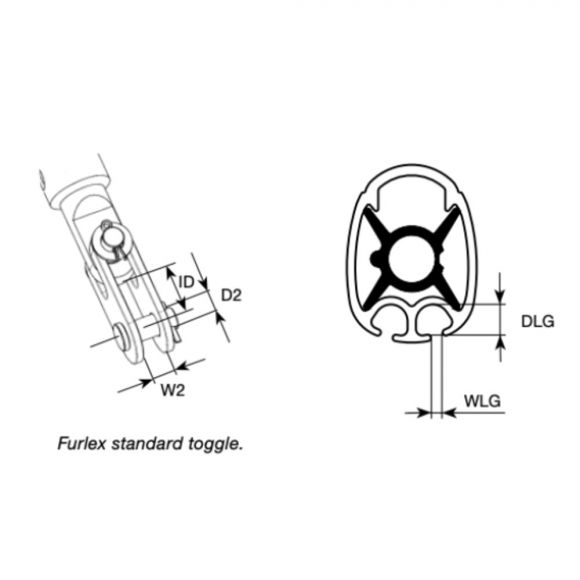

| ID | 1 1/4 in. | 31.00 mm. |

| W2 | 5/8 in. | 15.50 mm. |

| D2 – Clevis pin | 9/16 in. | 14.00 mm. |

| Max. Forestay length | 604 5/16 in. | 15.35 m. |

| Internal diameter of luff groove (DLG) | 1/4 in. | 6.00 mm. |

The fourth generation of the Selden Furlex is an uncompromising evolution of one of the world’s best selling jib furling and reefing systems. This proven design is blended with constant innovation as a way to maintain the iconic heritage of Furlex.

First thing to note is that the halyard swivel for Furlex 104S and 404S features stainless ball bearings and ball bearing races. The load on the top swivel is centered by the attachment of the Dyneema lashing. Selden’s patented load distributor for Furlex 204S and 304S makes for low furling resistance and durability. This concept was launched in 1983 and still performs flawlessly today.

The sail feeder is marine grade stainless steel. It is well rounded and non-abrasive to the sail. The twin-groove luff extrusion and the split drum allow the racing sailor to convert the Furlex for racing. The cruising sailor can use the extrusion for ‘wing on wing’ downwind sailing with two genoas poled out to either side. The forestay wire is centred and insulated the full length of the extrusion enabling the extrusion to rotate evenly around the wire.

The Furlex Aero Groove system reduces drag and creates improved flow over the luff extrusion and consequently, the sail. The furling resistance is reduced and chafe between the wire and the extrusion is eliminated. The luff extrusion consists of 2400 mm sections connected with an aluminium joining sleeve and a stainless steel connecting plate. The joining sleeve transmits the torque within the extrusions, and the connecting plates keep the sections together with a slight gap between them. This way chafe is avoided on both the extrusions and the sail. The Furlex Aero Groove system reduces drag and creates improved flow over the luff extrusion and consequently, the sail.

Similar to previous Furlex models, the standard kit requires that the wire is cut to length and fixed with a ‘Sta-lok’ mechanical wire locking system. A completely integrated rigging screw is offered as an option. It allows for adjustment of the forestay length without altering the height of the tack attachment.

Includes:

- New forestay wire

- Halyard lead

- Stanchion lead blocks

- Pre-feeder

- Furling line.

Our Part # SEL03502557 | Selden Part # 035-025-57

Features:

- Uniform cross-section of extrusion from head to tack for better performance of a reefed sail

- Single groove extrusion for 5 mm luff tape

- Stainless steel reinforcement in moulding of the Drum and Swivel

- High quality, glass fibre/polyamide composite used on sections of the drum assembly

- Stainless steel insert for low friction line management into the drum

- Fork/fork toggle for proper forestay articulation

- Stainless steel sail feeder for smooth hoisting of sail with composite connector

- Patented load distributor for easy furling and long service life

- Swivel utilizes ball bearingsand ball bearing rings in marine grade stainless steel

- Dyneema lashing is used to attach genoa halyard to the top swivel

Reviews

There are no reviews yet.